About inventory management

According to Investopedia, inventory indicates ‘the raw materials used to produce goods as well as the goods that are available for sale’ (Kenton, 2023) and is categorized into three key groups: raw materials, work-in-progress (WIP), and finished goods. For many businesses, it represents money, whether it’s revenue or cash, regardless of its stage. Thus, managing inventory is an important task in the supply chain since it helps companies pinpoint the precise stock to order at the right time and track these raw materials throughout the supply chain lifecycle, from manufacturers to warehouses to points of service.

For many suppliers and manufacturers, having a strong and visible inventory management can strengthen a business’s supply chain process while avoiding pitfalls such as slowing down cash flow, shipment turnaround, and stockouts.

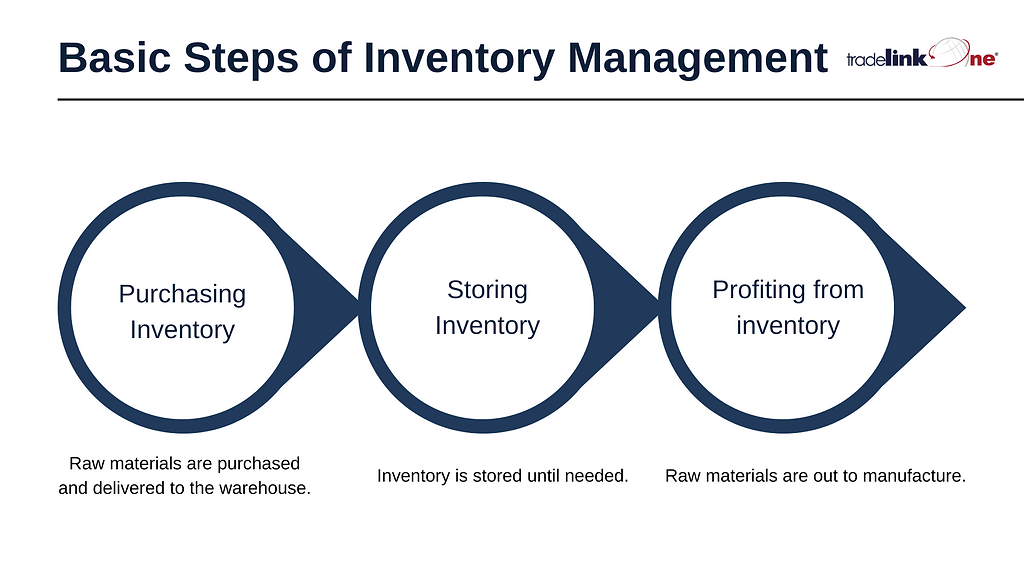

Three steps in inventory management

It is worth noting that the type of inventory to be circulated can vary depending on your business model. If you are a buyer, raw materials should be converted into ready-to-sell goods stored in the warehouse or delivered directly to service points. Nonetheless, it is crucial to control the inventory stock level to meet order fulfillment for all business partners.

Three types of inventory management

Periodic inventory management

Periodic inventory management involved physically counting inventory at set intervals. It is commonly used for financial reporting, calculating the cost of goods sold (COGS) by adding and subtracting additional and ending inventory throughout that interval. Due to its physical accounting nature and low implementation cost, periodic inventory is a popular practice among small businesses.

Barcode inventory management

A barcode is assigned to each inventory, containing various information such as ID number, supplier, category, and more. As the inventory enters storage facilities and navigates through the supply chain, it is accurately tracked by the business’s barcode inventory management software. Depending on size, orders, and infrastructure, many medium to large-sized businesses integrate this technology into their organization.

RFID inventory management

Radio frequency identification (RFID) uses radio frequency to identify and track tagged inventory, assisting businesses in recording information and tracking real-time status throughout the supply chain process. The chip attached to the inventory can not only record more information but also be scanned from long distance, thereby providing greater visibility and accuracy in supply chain.

Conclusion

Inventory management is a crucial process to help businesses control the right amount of inventory while catering their business partner or customer’s demand and preventing many costly risks. Many businesses follow three fundamental steps in controlling their stocks, yet their method can differ as each technology is beneficial to a specific business scale and infrastructure.

—

About TradeLink Technologies,

TradeLink Technologies, founded in 1999, is a supply chain technology solutions provider for global and retail companies. We provide a complete set of packing and shipping solutions to enhance accuracy and visibility using the latest in barcoding technology, including RFID. Learn more about the technology and TradeLink here.