What Is Traceability?

According to ISO 9000:2015 standards, traceability is the ability to trace the history, application, use and location of an item or its characteristics through recorded identification data. It enhances the transparency of monitoring and tracking processes throughout a product’s lifecycle.

In the fashion industry, identifying each material and component used in garment production brings clarity on the product’s origin. Traceability data ensures that all parts of the clothing is sourced ethically and produced under safe working conditions..

The Challenge Of Traceability

With consumers becoming more concerned with product quality, transparency, and regulatory compliance, it’s no wonder that traceability is gradually becoming a widely discussed trend. Beyond consumer benefits, traceability plays a credibility guarantee role for businesses seeking a supply chain transparent and sustainable practices. Its trendiness leads Vietnamese garment and footwear businesses to gradually shift towards sustainable development, aiming for transparency in the product origin and production methods. However, businesses still experience significant gaps on the path achieving effective traceability.

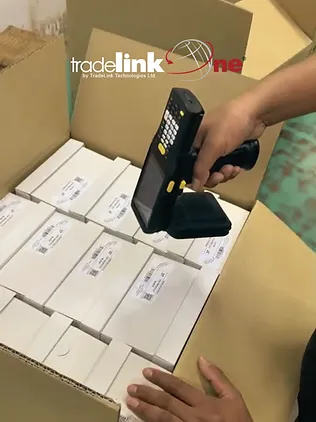

To track items effectively, each one needs a unique code. Currently, most codes are manually created and do not follow GS1 standards. This allows companies to track items internally. However, when these products reach the market, duplicate code between different products can occur, making traceability ineffective. Additionally, while technologies such as barcodes and RFID are used at various stages of production, applying them in isolation without integrating all processes cannot bring a complete picture throughout the product’s journey.

Finding Pioneer Enterprises

TradeLink Technologies has provided supply chain technology solutions for global companies and retailers in more than 25 years. Our solutions apply the most advanced technologies, aiming for transparency, visibility, accuracy in a seamless supply chain.

Narrowing Decades Of Gray Market With Traceability

In 2023, TradeLink partnered with a high-end fashion and outdoor accessories brand to enhance product transparency and prevent the gray market.

Traceability brings many benefits, including the gray market prevention, a major issue that directly impacts on luxury goods, such as those from this brand. The gray market has continuosly decreased the company’s revenue, customer trust, and leads to tax losses for governments.

Previously, each item of this brand was labeled with a security code known as the “Ship to” code, which indicated the product destination. This code was sewed onto the product tag. If there were suspicions that goods were not distributed legally, the brand could use the “Ship to” code to verify whether or not the product destination code matched its current location, thus confirming its legal distribution.

QC Label and “Ship to” Code

In today ‘s market, brands need flexibility in their distribution processes. The manual and fixed “Destination” code significantly reduces flexibility; therefore, shipments can only be sent to the exact location sewed on the product tag.

Embracing Serialization Solution For The Gray Market

With the desire to create a flexible supply chain, combined with the traceability needed, TradeLink implemented a traceability project using QR codes to display product information. TradeLink Technologies’ strength lies in its experience with serialization solutions, identifying products at the item level.Traceability QR Code

The information on QR code includes:

- Country of Manufacture

- Manufacturing site

- Date of manufacture

- Destination

Traceability QR code

This allows the brand, manufacturer, and customers to easily trace the product’s origin by scanning the QR code. Additionally, the serialization solution can update product information even after the product has left the factory and reached the distribution centers, enhancing flexibility for brand’s distribution. The traceability project has exceeded expectations, paving the way for a transparent supply chain, increasing consumer trust, and contributing to market stability.

RFID – The Essential Technology Trend of the Apparel Industry

“Unlock Tomorrow with RFID Technology” Event, organized by TradeLink, with the participation of 30 apparel and footwear businesses in Ho Chi Minh City.

RFID, or Radio Frequency Identification, is considered to be the most effective technology for traceability. RFID can surpass traditional barcode technology with the ability to identify objects via radio waves without direct line of sight.

A key feature of RFID tags is their ability to be serialized and have unique identification code, which makes counterfeiting difficult and enhances product security and authenticity. Integrating RFID technology with Digital Product Passport (DPP) can greatly improve the accuracy and accessibility of product information, boosting traceability. As DPP promises to be a new standard in the textile and fashion industry, RFID has a huge potential to become an essential trend.

Global brands that are TradeLink’s clients have switched from barcode technology to RFID years ago, leveraging this technology in packing and inventory management at stores. Leading garment factories in Vietnam have also proactively reached TradeLink to implement RFID technology in their factories, preparing for the traceability wave in Vietnam.

RFID Application in Footwear Industry

RFID Application in Packing Process

TradeLink believes that issues in the supply chain often occur in the origin of the supply chain, involving raw material suppliers and manufacturers. Therefore, we focus on developing RFID solutions that ensure data transparency, accuracy, and reliability. Now, even though RFID is increasingly popular among TradeLink’s customers, considerable effort will be needed to spread this technology across the entire supply chain. Implementing RFID technology from raw materials to the final product will provide complete information about the product’s origin and entire journey.

More about TradeLink at: www.tradelinkone.com